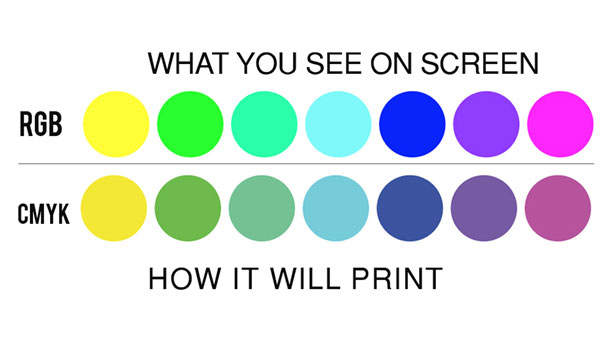

Our print house is one of the ways we save your business time and money. The production of artwork is one of the most time-consuming aspects when it comes to printing and cutting graphics. There are so many steps involved before a job is ready for application.

To assist you, we have created one of the most technological advance print studios. This will help ensure that you meet your customer deadlines on time by not running yourself or your staff thin.

At your disposal, you have: